How to Choose Garment Bag Fabric: A Professional Guide to Materials & Weight

Selecting the right Garment Bag Fabric is a critical decision that impacts product protection, brand perception, and cost. This guide simplifies the choice between Oxford cloth, non-woven fabric, canvas, cotton, and nylon by focusing on key technical specs: D number (Denier) for synthetics and GSM (grams per square meter) for non-wovens.

Key Materials Explained: From Oxford Cloth to Cotton

Understanding material properties ensures optimal protection for garments.

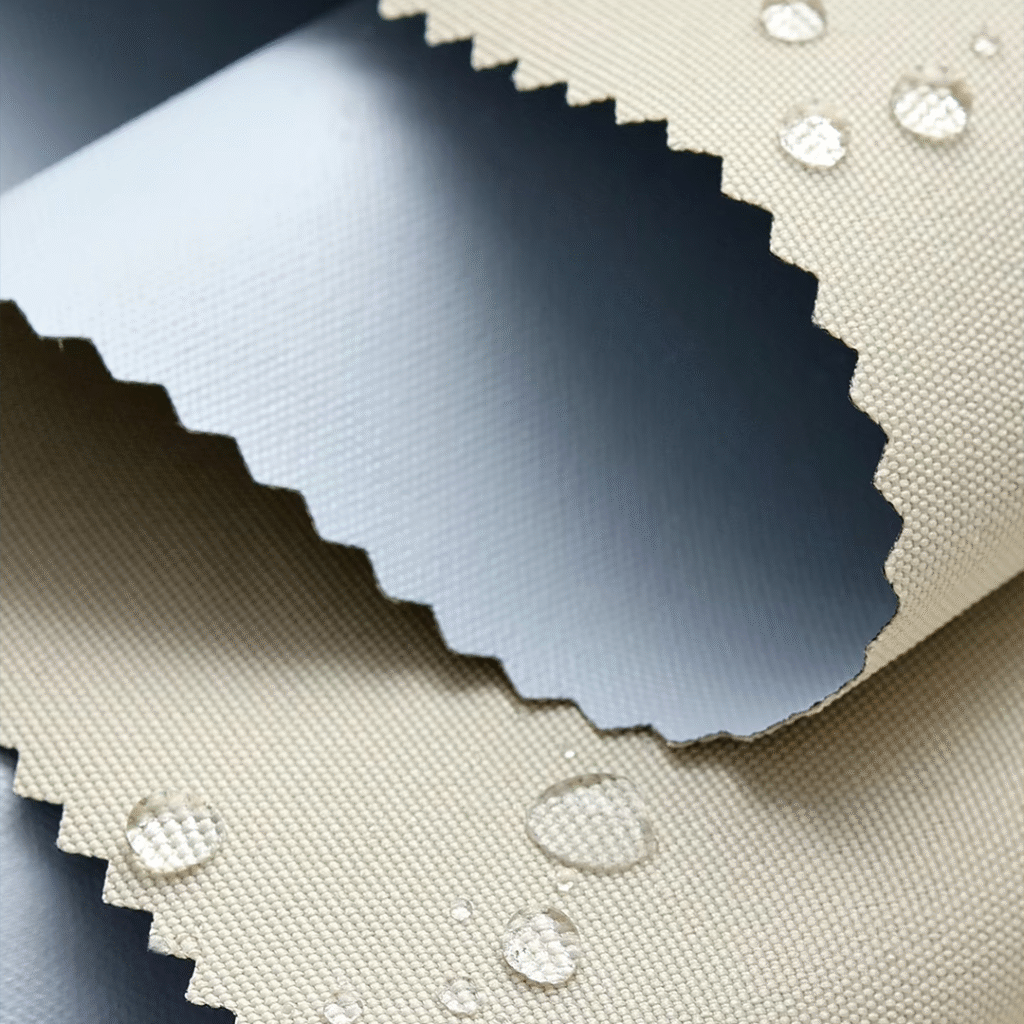

Oxford Cloth:

D Number Range: 210D (lightweight), 300D (standard), 600D (heavy-duty).

Pros: Durability, water resistance (with PU coating), cost-effectiveness. Ideal for frequent travel and mid-range retail bags

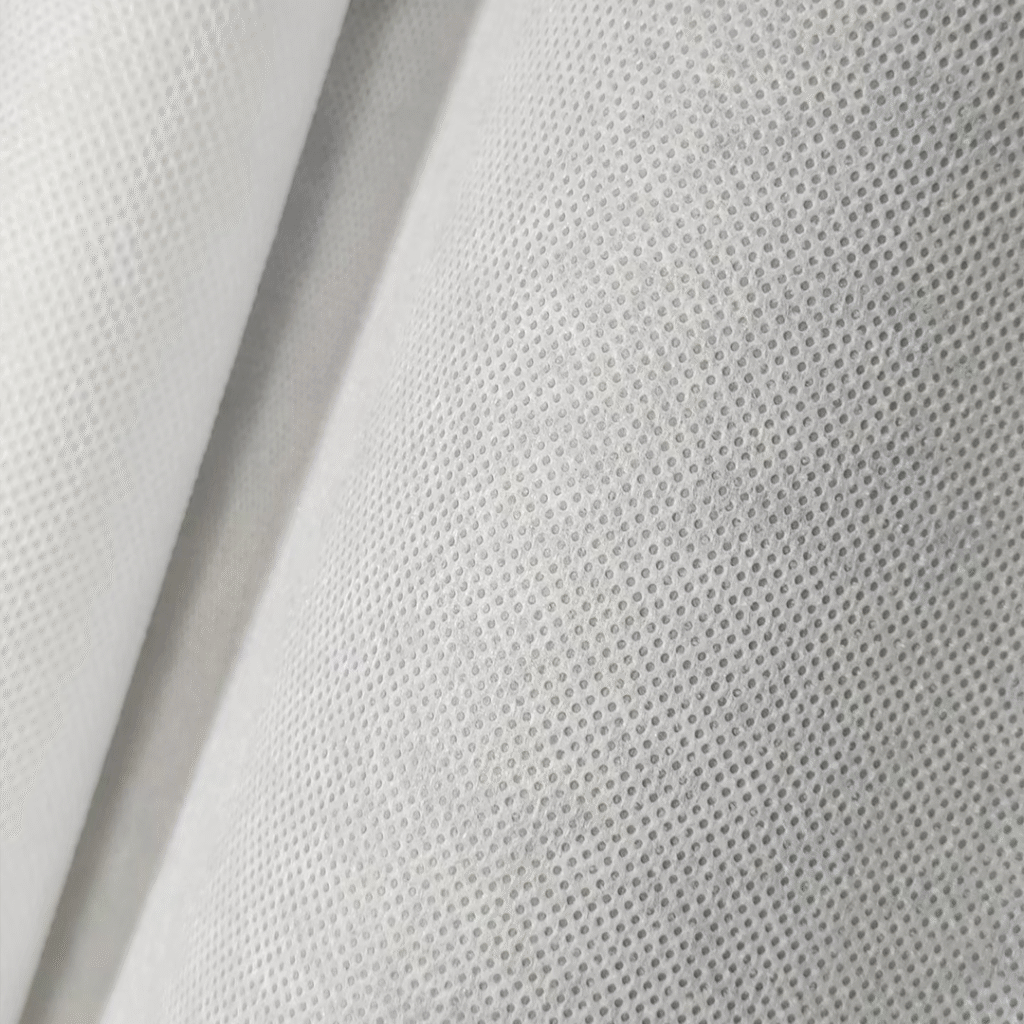

Non-Woven Fabric (NWPP):

GSM Range: 50–80 GSM (lightweight dust covers), 80–110 GSM (standard protection), 120–200+ GSM (heavy-duty).

Pros: Lightweight, affordable, recyclable. Best for e-commerce shipping and short-term storage

Cons: Prone to tearing; less premium perception.

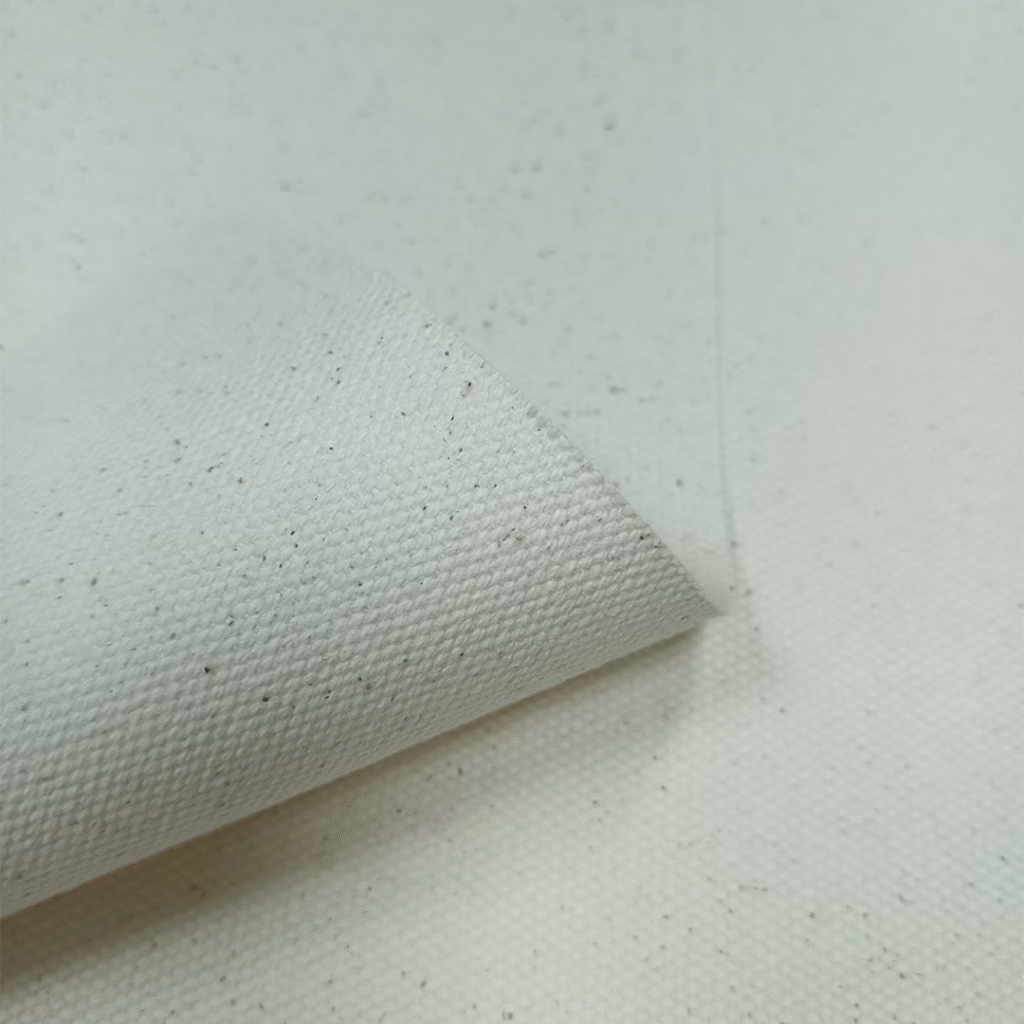

Canvas:

Weight Options: 6 oz (lightweight) to 16 oz (heavyweight).

Pros: Extreme durability, eco-friendly (natural cotton), reusable. Perfect for luxury storage and heavy garments

Cons: Heavy; requires water-resistant treatment.

Cotton:

Weight Options: 6–8 oz (breathable covers), 12–16 oz (structured storage).

Pros: Breathability, sustainability, mold prevention. Ideal for delicate fabrics (wool, silk) and long-term storage

Cons: Not water-resistant; wrinkles easily.

Nylon:

D Number Range: 210D (light), 420D (standard), 600D (heavy-duty).

Pros: Lightweight, tear-resistant, waterproof. Best for travel and high-transit environments

Cons: Less eco-friendly; synthetic feel.

How to Match Fabric to Function: 5 Critical Factors Select materials based on practical needs rather than cost alone.

Durability Needs:

High-Durability: Choose 600D nylon or 16 oz canvas for travel/rough handling.

Moderate Use: 300D Oxford cloth or 110 GSM non-woven suffice for retail storage

Environmental Conditions:

Humid Climates: Waterproof materials like nylon or PEVA prevent moisture damage

Dry Storage: Breathable cotton or canvas prevent mildew in long-term scenarios

Sustainability Goals:

Eco-Friendly Options: Recycled Oxford cloth (rPET) or organic cotton reduce environmental impact

Budget Constraints:

Economical: Non-woven fabric (50–80 GSM) for bulk, short-term use.

Premium: Heavy cotton/canvas or 600D nylon for luxury branding

Aesthetic & Branding:

High-End Perception: Cotton/canvas with custom printing elevates unboxing experiences.

Visibility: Clear PEVA bags allow product identification without openin

Application-Based Recommendations Tailor choices to specific use cases for maximum efficiency.

4. Application-Based Recommendations

Tailor choices to specific use cases for maximum efficiency.

E-Commerce Shipping:

80–120 GSM non-woven bags balance cost and protection for standard apparel

Luxury Retail Storage:

8-12 oz cotton canvas with custom branding for high-end garments

International Travel:

400-600D nylon with reinforced stitching for abrasion resistance

Long-Term Archival Storage:

Breathable cotton with acid-free properties to prevent yellowing

Conclusion: Smart Selection Saves Costs & Enhances Brand Value

Garment bag fabric is a strategic investment, not an expense. Prioritize material specs (D number, GSM, weight) over aesthetics alone to ensure garments remain protected from production to delivery.

Next Steps:

Request material swatches from suppliers to test durability.

Prototype bags under real conditions (e.g., simulate transit stress).

Align with sustainability certifications (GRS, FSC) for market competitiveness

Need Expert Guidance?

ANG specializes in custom garment bags for global fashion brands. Contact us for a free consultation and material sample kit.